Medical Device Machined Components

Medical Device Machining

At Camco Precision Machining, we manufacture precision medical device components and robotic parts for high-performance applications. Our capabilities include CNC machining, CNC Swiss machining, lathe turning, and milling, enabling us to provide high-quality parts for both medical devices and robotic systems. We produce a wide range of parts, including surgical robotic components, single-use robotic tools, and other precision parts for the medical industry.

Robotic Components for Medical Applications

We produce various single-use robotic components such as robotic grippers, clips, forceps, and surgical tools used in robotic-assisted surgeries. These tools include graspers, scissors, needle holders, and bipolar forceps, all requiring extreme precision for effective use in robotic-assisted surgery. These parts are typically precision-machined from high-performance materials like titanium and stainless steel using CNC Swiss machining, CNC turning, and milling.

Our CNC lathe turning and milling capabilities allow us to produce parts with the high tolerances necessary for small, intricate components used in robotic arms and surgical tools. Whether creating articulating tips for graspers or precision clips for securing robotic components, our machines can produce parts for complex robotic mechanisms that support surgical efficiency.

Other Medical Device Machining Components

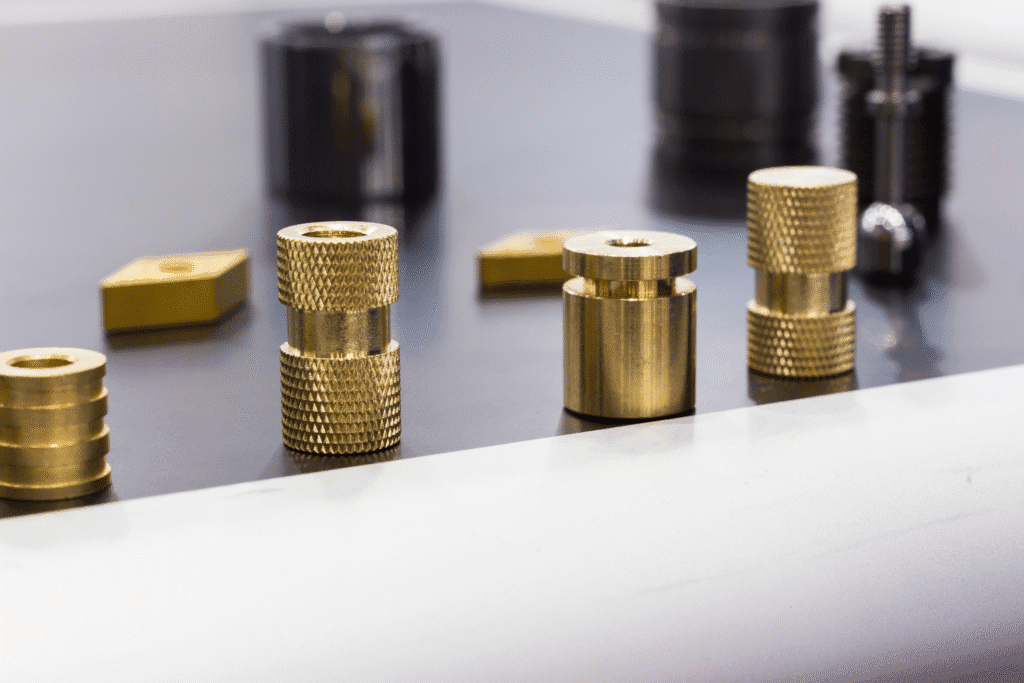

In addition to robotic components, we manufacture precision medical components including surgical tools machining, prosthetic parts, and orthopedic devices. Using CNC Swiss machines and CNC lathes, we create connectors, surgical tools, custom machined dental parts and other critical components that meet the demanding standards of the healthcare industry. These parts are crafted from materials such as titanium, stainless steel, and medical-grade plastics, ensuring reliability and performance in medical applications.

We also specialize in manufacturing bone screws, pedicle screws and other small, intricate medical components. These parts are ideal for orthopedic applications, where precision is crucial. Swiss machining and screw machining are particularly well-suited for producing bone screws and small threaded components with tight tolerances and fine finishes. We work closely with OEMs in the medical device industry to provide parts that meet stringent FDA and ISO standards, ensuring reliability and biocompatibility for use in medical procedures.

- High Precision & Tight Tolerances: Our machines, including CNC Swiss, lathe turning, and milling, produce high-precision parts for robotic and medical applications with tight tolerances to ensure reliable performance.

- Material Flexibility: We work with a wide range of biocompatible materials such as titanium, stainless steel, and medical-grade alloys, ensuring that each part is designed for optimal performance in its specific application.

- Versatile Machining Capabilities: We have the equipment to run a variety of parts on CNC Swiss machines, CNC lathes, and milling machines, offering flexibility in production and ensuring we can meet the needs of both robotic surgery and medical devices.

We are a medical machining supplier committed to providing high-quality, reliable parts for robotic systems and medical devices that drive advancements in healthcare. Whether you’re looking for precision surgical tools, robotic arm components, or other medical device parts, we can deliver the components you need for critical medical applications.

Request a Quote

If you’re looking for precision robotic components or medical device parts, ask us a question or request a quote below today. As a proven medical device manufacturer, we are ready to help you meet the exacting standards of the medical and robotics industries.

Machining Capabilities

High-precision parts using advanced CNC Swiss machines.

Orders up to 1,000,000+ pieces efficiently produced.

Continuous, automated production from metal bar stock.

Multi-spindle lathes with live tooling for complex parts.

Enhanced efficiency and cost savings for high-volume runs.

Versatile machining for complex shapes and features.

Connectors, Mounting brackets, Heat sinks, PCB components, Electrical terminals and more.

Trigger components, Magazine parts, Barrel bushings, Firing pins, Gun receiver components and more.

Valve seats, Pump components, Seals and gaskets, Nozzles, Couplings and more.

Threaded inserts, Heat-set inserts, Retaining rings, Standoffs, Bushings and more.

Valve components, Pressure seals, Pump shafts, Manifold parts, Couplings and more.

Air cylinders, Pressure regulators, Pneumatic valves, Piston rods, Air fittings

Ask a Question

Camco Precision Machining

4701 Haag Drive

Union Grove, WI 53182

262-878-4700

Local to Wisconsin and Chicago, Shipping Quality Machined Parts Nationwide Since 1981.